C79- EXPANSION BOARD Rev. 2

APRIL, 2025

1.0 OVERVIEW

This card provides an easy way to connect your inputs and outputs from your port using a LPH26pin Ribbon Cable or parallel port. Provides terminals for connections and conditions signals for use in CNC applications; this version can be easily mounted on control boxes using DIN rails and can also accommodate ribbon cables or DB25 connectors.

2.0 FEATURES

- Terminal Block for all I/Os.

- Buffered outputs.

- Open collector Outputs, Pins optoisolated 1, 14, 16, 17.

- Compatibility with several Motion Controllers and motherboards. C76, M16D, UC300ETH-5LPT, C92, and ESS expansion board.

- Input pins 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15.

- Terminal Block input with close-by ground or +5vdc connections, COM, and outputs with + 24vdc and ground

- Screw-On connections for all terminals. You only have to screw-on the wires to make all your connections.

- Status LEDs for enabling.

- Fully Optoisolated Inputs and Outputs.

- External Enable Pin

- Din rail mountable.

- Pluggable Screw-On Terminals.

3.0 SPECIFICATIONS

|

DIGITAL INPUT SPECIFICATIONS |

|

|

On-state voltage range |

24V DC |

|

Maximum off-state voltage |

0.8V |

|

Maximum operation frequency |

4 MHz |

|

Typical signal delay |

10nS |

|

OPEN COLLECTOR OUTPUT SPECIFICATIONS |

|

|

Maximum output voltage |

60VDC |

|

Maximum output current |

2Amps |

|

Typical signal delay |

0.5 µS |

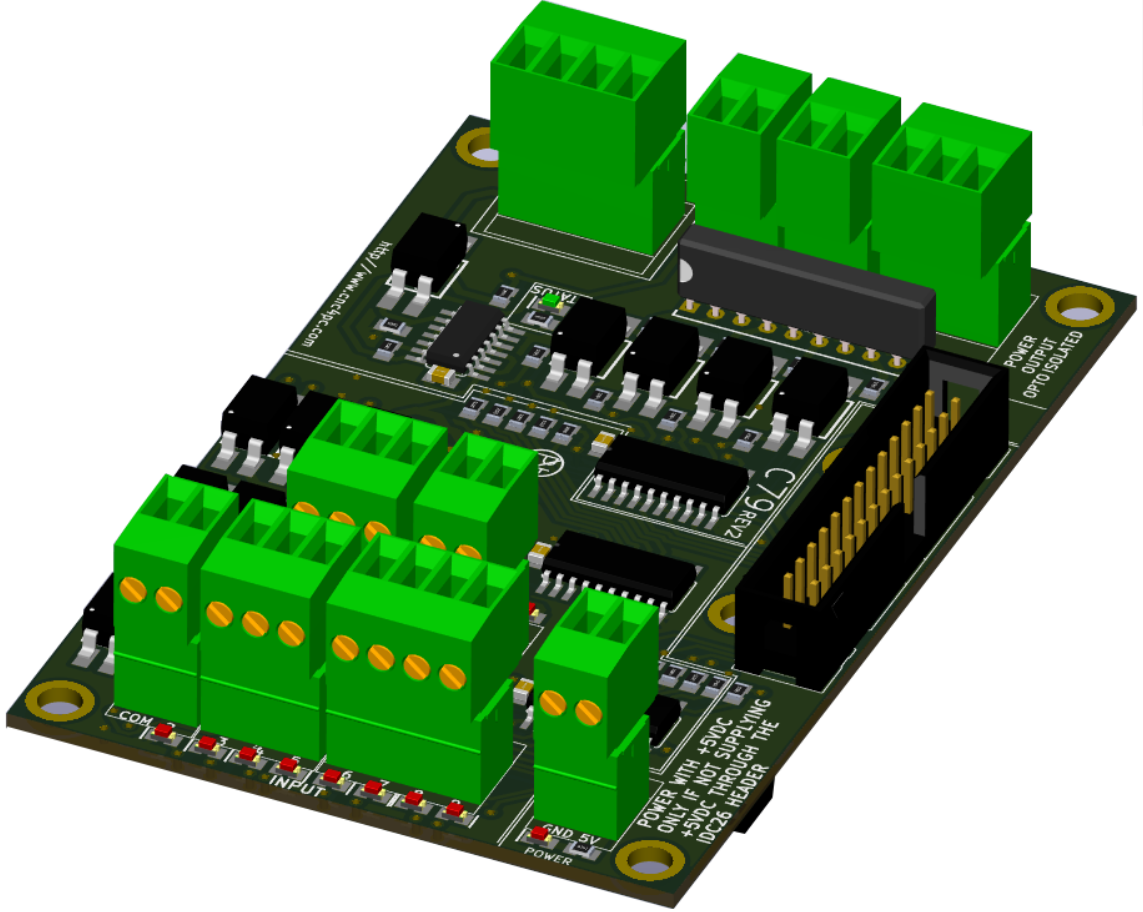

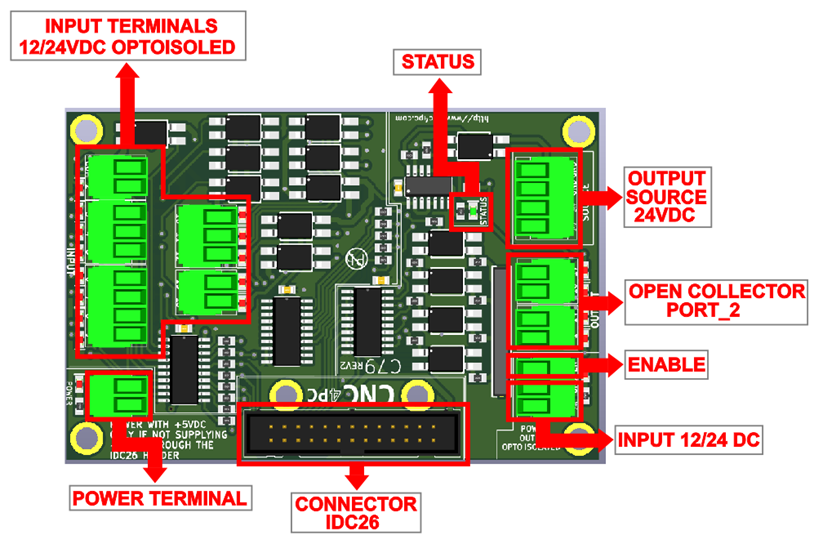

4.0 BOARD DESCRIPTION

5.0 REQUIREMENTS

5.1 Power Requirements

Regulated +5VDC, which can be supplied through pin 26. +12 or 24VDC is required to power the Open Collector Outputs and Optoisolated Inputs.

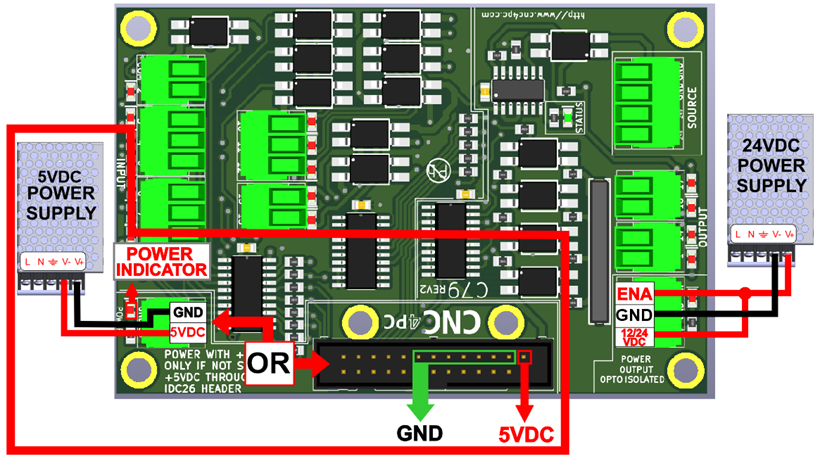

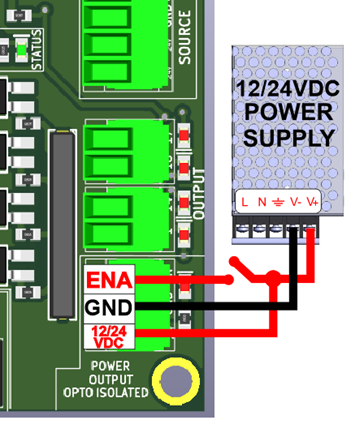

6.0 POWER TERMINAL

To preserve optoisolation two independent power sources should be used.

A +5Vdc to power the logic and optos that interact with the controller. Since these are isolated, they can come from a USB cable or pin 26 on the IDC26 connector. The +12/24VDC at 200 Amp will power the Open Collector Outputs and Inputs.

6.1 Enable pin.

The card must be provided with a 24VDC signal to enable operation. This feature has been added to externally control the status of the outputs. An external switch or a Safety Charge Pump can be added to provide the enabling signal. If this function is not required, a jumper can be placed between 24VDC and the EN terminal.

If using it with the C76 or M16D using an IDC26 to IDC26 ribbon cable, you can leave a jumper on the EN terminal and allow the motherboard to control the enable. The C79 will be enabled when the motherboard is enabled. This is done through pin 18 of the IDC26 connector.

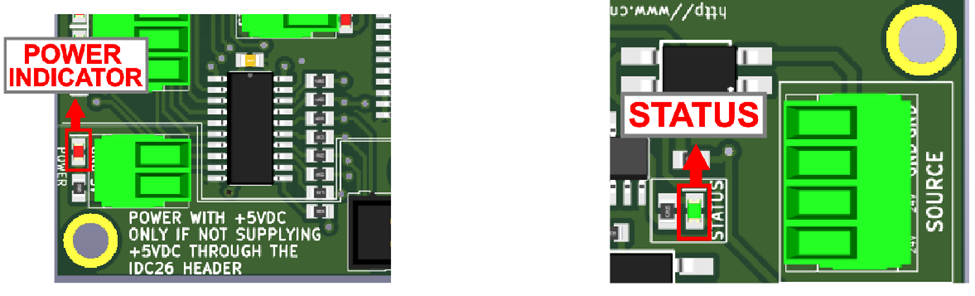

7.0 INDICATOR LED

The power LED lights indicate that the system is ready but disabled. When Status LED, (Green LED) lights, it indicates that the system is enabled.

8.0 PINOUT

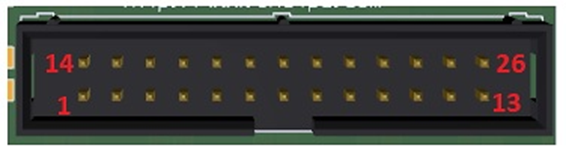

8.1 Pin numbering

8.2 IDC26

|

IDC26 Pin number |

LPT port direction signal

|

|

1 |

Output 1 |

|

2 |

Input 2 |

|

3 |

Input 3 |

|

4 |

Input 4 |

|

5 |

Input 5 |

|

6 |

Input 6 |

|

7 |

Input 7 |

|

8 |

Input 8 |

|

9 |

Input 9 |

|

10 |

Input 10 |

|

11 |

Input 11 |

|

12 |

Input 12 |

|

13 |

Input 13 |

|

14 |

Output 14 |

|

15 |

Input 15 |

|

16 |

Output 16 |

|

17 |

Output 17 |

|

18 |

Watchdog (Ground to Enable) |

|

19 - 25 |

GND |

|

26 |

+5VDC |

8.3 Compatibility

|

CONTROLLERS |

PORTS |

|

C76 |

3 |

|

M16D |

3 |

|

ESS |

2 |

|

5LPT |

1, 4, 5 |

|

C92 |

1,2,3 |

9.0 CONFIGURATION SWITCHES

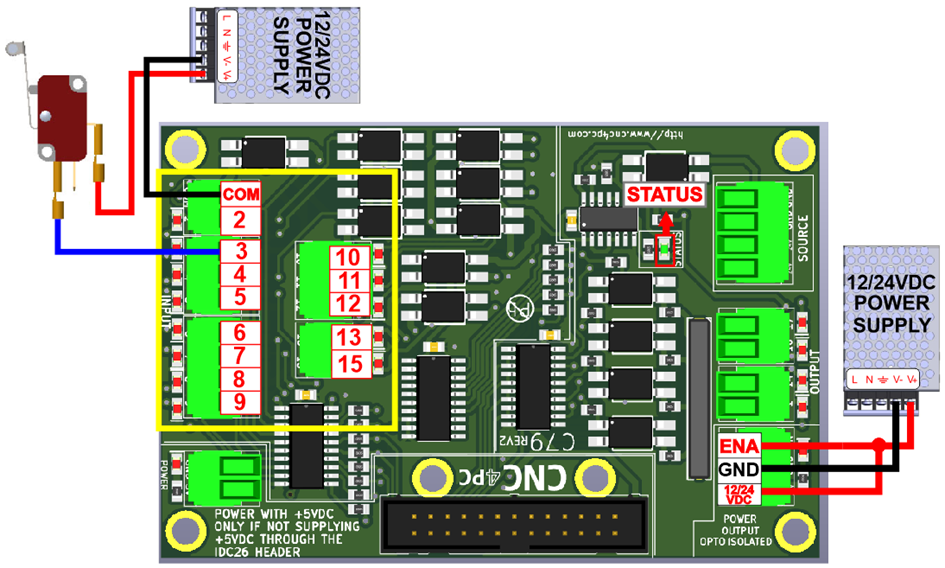

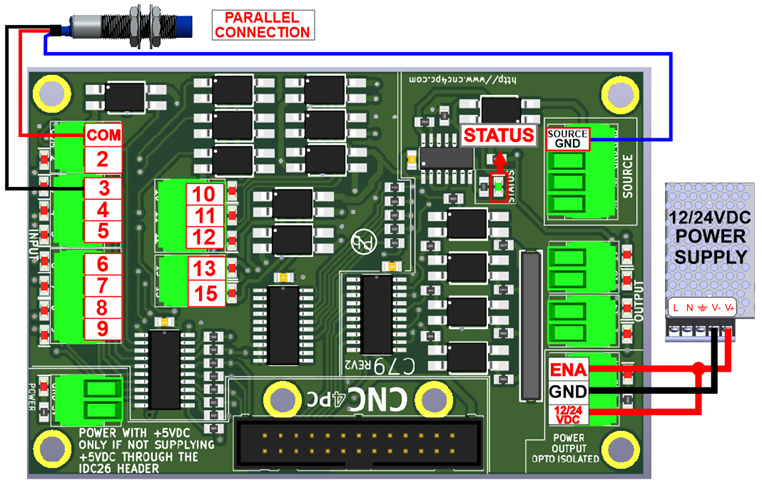

9.1 Connecting Switches Using the COM = GND

There is a jumper that allows you to select +12/24VDC or GND for the COM pins.

While this board supports input +24VDC signals, different kind of sensors, switches using different voltages can be connected using the diagrams that follow:

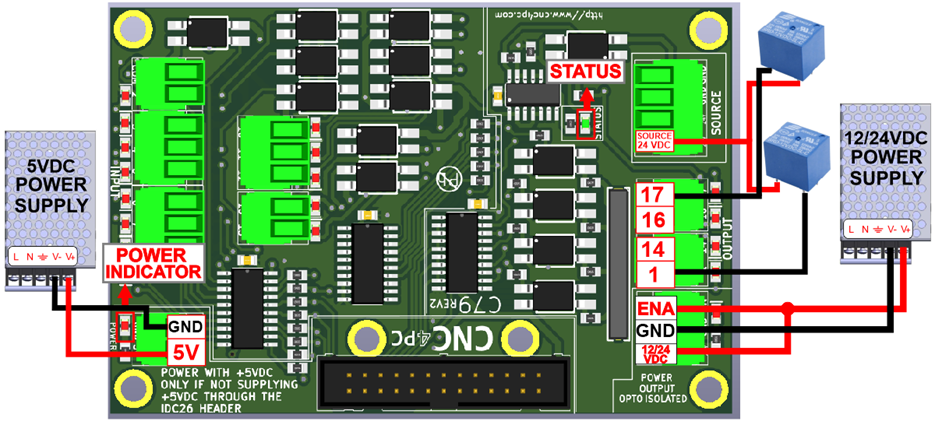

Fig. 1 Wiring diagram to connect switches.

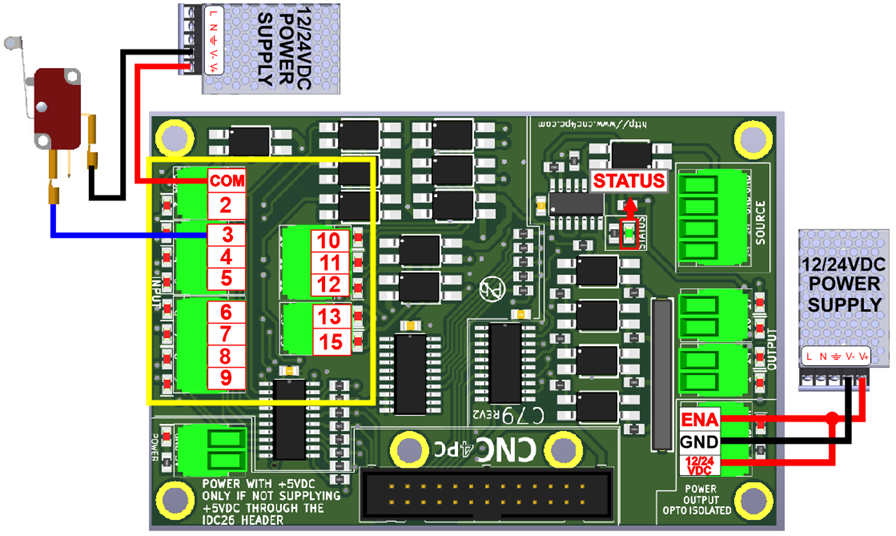

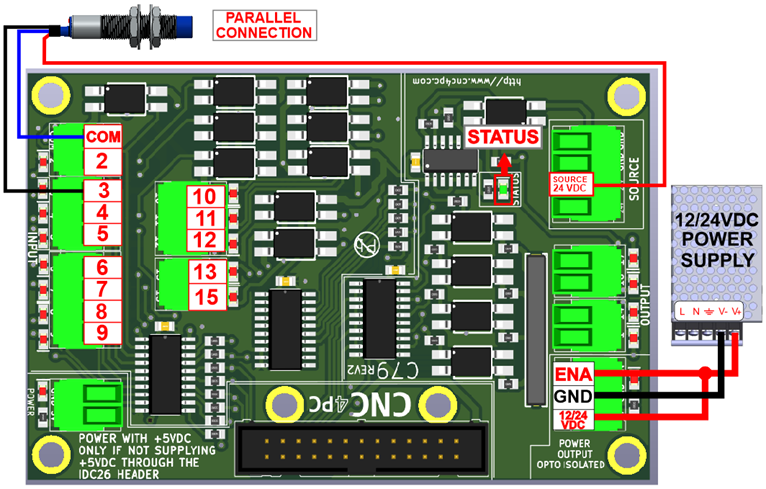

9.2 Connecting Switches Using the COM = 12/24VDC

Fig. 2 Wiring diagram to connect switches.

10.0 EXAMPLE WIRING OPTOISOLATED OUTPUT

The power source of 12/24 VDC is

for the correct functioning of the outputs (1,14,16,17).

11.0

WIRING

DIAGRAM SENSORS

11.1 Connecting PNP sensors.

Fig. 3 Wiring diagram to connect PNP open collector proximity sensors.

11.2 Connecting NPN sensors.

Fig. 4 Wiring diagram to connect in parallel NPN open collector proximity sensors.

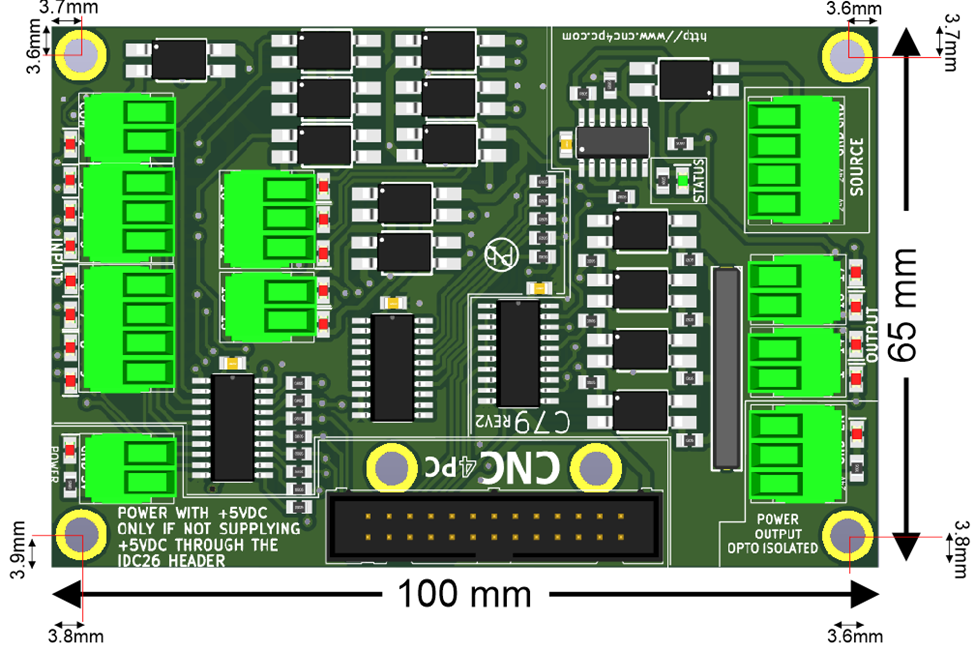

12.0 DIMENSIONS

All dimensions are in Millimeters.

Fixing holes (4mm).