THC-1 - TORCH HEIGHT CONTROL

MAY 2023

TABLE OF CONTENTS

1.0 OVERVIEW

This

module allows controlling the height the plasma torch head relative to work

piece during plasma CNC operation, it supports either raw torch head voltage or

an input of 0-10VDC, the ARC OK, UP and DOWN outputs are isolated.

2.0 FEATURES

- Open collector to optoisolated output working at 5 to 24VDC.

- Built-in Voltage Divider for connecting to the voltage on the torch or can use the 0-10VDC from a voltage divider from the plasma.

- LCD Screen.

- 10 to 30VDC Power Terminal (+24 Typical).

- Isolated Power Connection.

- Din Rail Mountable.

- Divider input.

3.0 DESCRIPTION

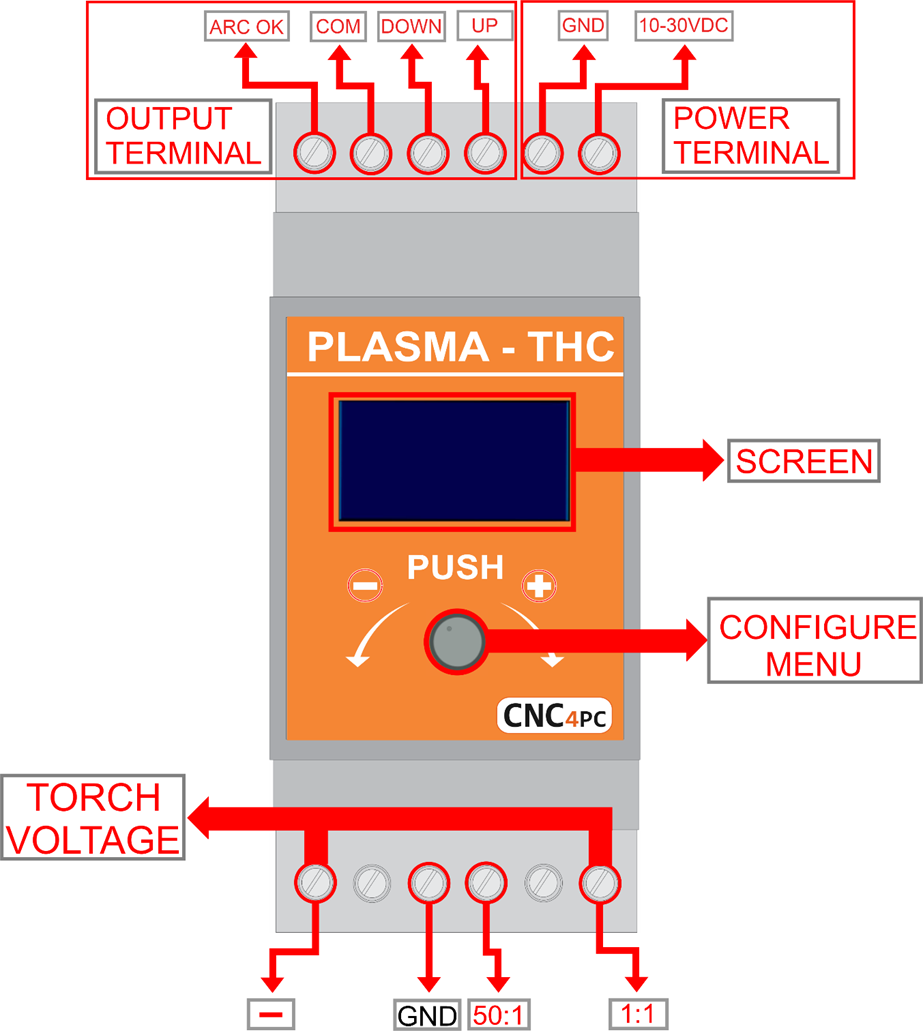

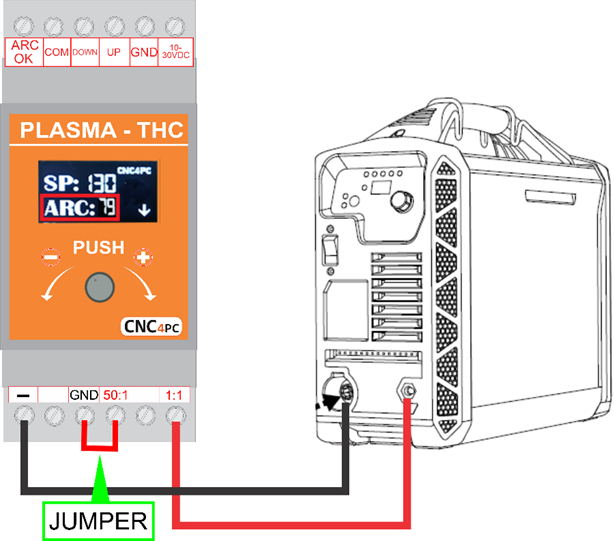

4.0 TERMINAL BOARD

4.1 POWER

Requires a 10 to 30VDC at 100mA Power Supply, “This board is electrically isolated through a DC-DC converter.”

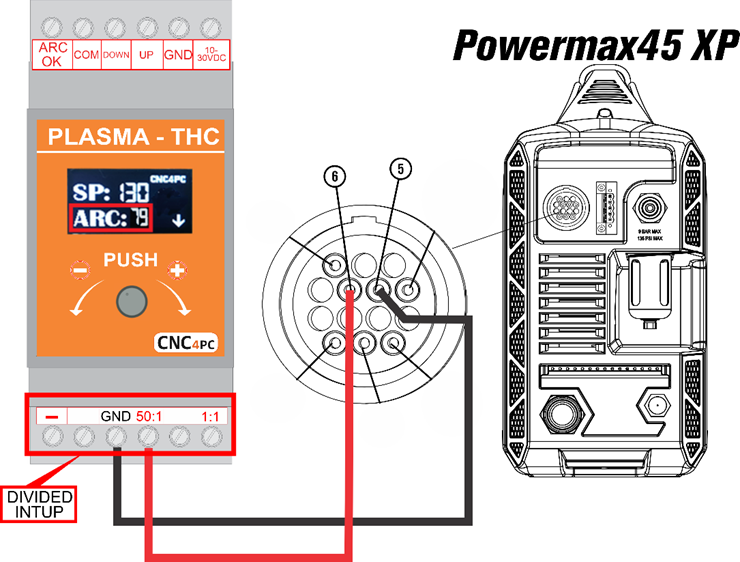

4.2 DIVIDED INPUT

4.3 TORCH VOLTAGE

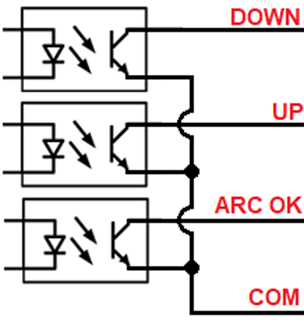

4.4 OUTPUT SIGNALS

Voltage applied can be from 5 to 80VDC@50mA, outputs signal optoisolated Open Collector.

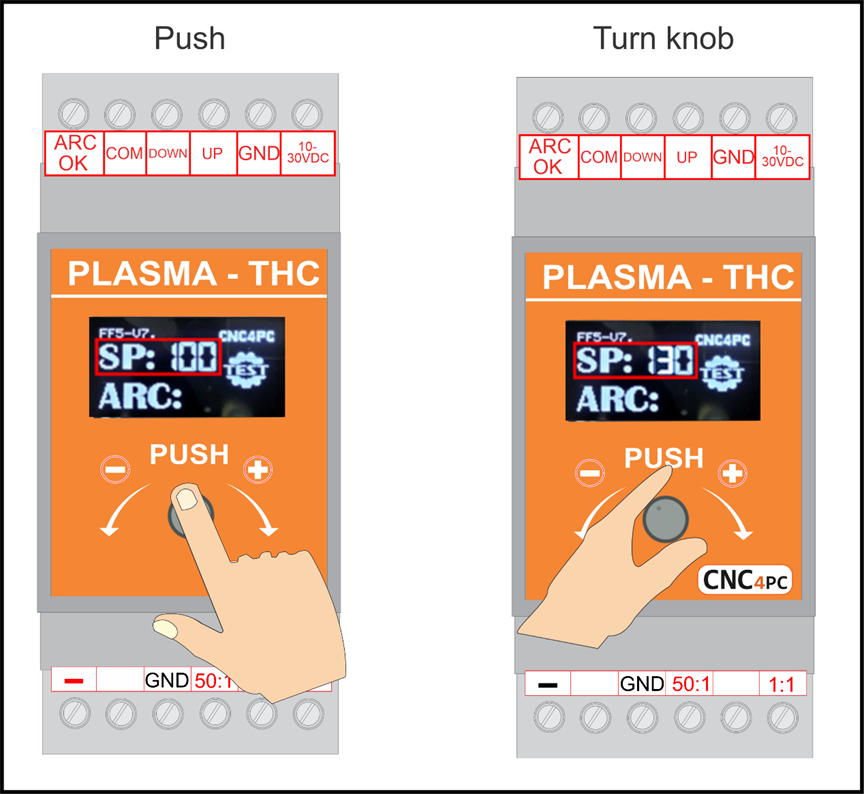

5.0 CONFIGURE MENU

- Push the knob to enter configuration mode.

- Navigate through the configuration menu by pressing the knob.

- Turn the knob to adjust the value.

- Push the knob to set the value and navigate to

the next parameter or until you reach the run mode.

6.0 DESCRIPTION SCREEN

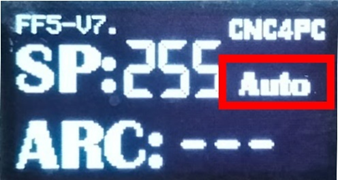

6.1 SET POINT (SP)

SP is the target voltage to be achieved.

6.2 VOLTAGE ARC (ARC)

Limit from 40 to 400VDC, True Voltage measured at the terminals or the voltage divider.

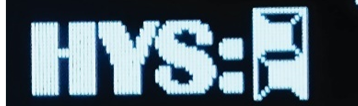

6.3 HYSTERESIS (HYS)

Is the tolerance or (+/-) voltage range used to generate an adjustment. The torch height is not commanded to adjust if the true voltage is inside the specified range. It can be between 2 to 32VDC.

6.4 DELAY TIME (DT)

Torch motion starts the number of seconds you set as DT after the ARC signal is determined. This can be a value between 0.1 to 9.9 seconds.

6.5 TEST MODE (TEST)

- Press the knob three times to enter test mode.

- Turn the knob up or down to adjust the spindle's movement.

- To exit test mode, press the knob once.

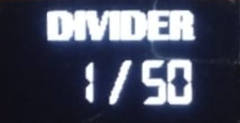

6.6 DIVIDED VOLTAGE CONFIGURATION

- Press the knob three times to enter the setting mode

- Turn the knob to adjust the value.

- Press the knob to set the split voltage

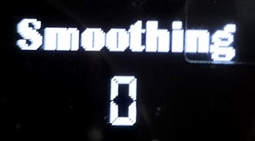

6.6 ANALOG SMOOTING

This data smoothest the voltage reading. This can be a value between 0 to 3.

6.7 ANTI-DIVE

If the plasma torch moves over space, the THC will see it as a voltage spike. Setting a max voltage value will allow the THC to ignore the voltage spike and prevent the torch from dying. This can be a value between 50 and 300V.

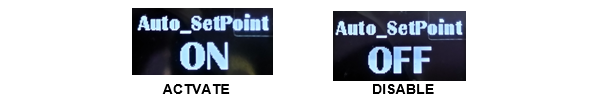

6.8 AUTO_SETPOINT

Automatically establishes the SetPoint based on the specified cutting height.

If auto_SetPoint is activated the knob it's disabled and the word Auto is displayed on the screen

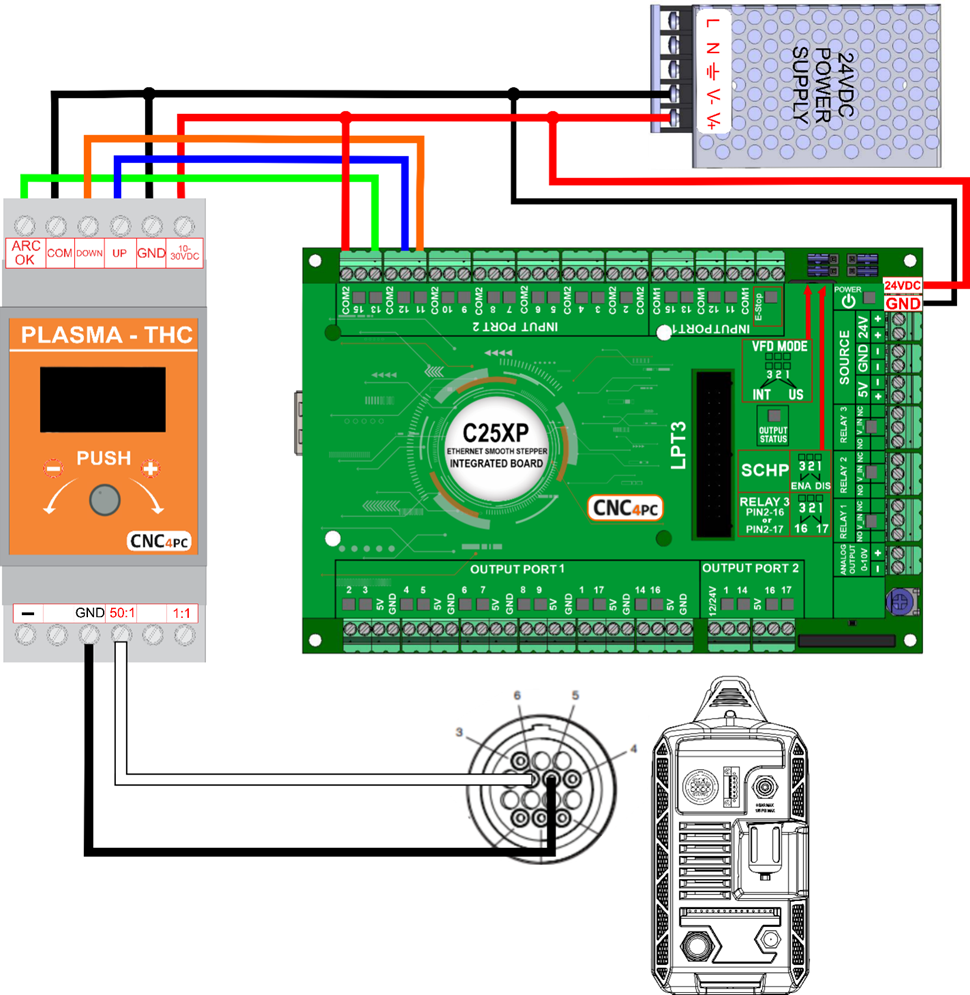

7.0 WIRING SAMPLE