Acorn Torch Height Controller (THC)

Centroid Acorn THC controller kit includes:

- THC TX control board

- THC RX control board

- 5' Fiber Optic Cable ( TX to RX connection)

- 12" Shielded Serial Cable M/F Straight ( RX-to-Acorn connection)

- Din Rail Mount 24 volt power supply

Requirements:

- Acorn CNC controller kit.

- A Hypertherm Powermax Plasma Cutter or Lincoln Flex Cut! (see FAQ's below)

- An Acorn CNC12 Plasma Pro software license (purchase below)

|

Centroid Acorn Plasma Feature Highlights Closed Loop THC: Real time closed loop operation between the Arc Voltage and the Torch Height. Fiber Optic Isolation. PID THC control. Restart Mode: Restart any where along the contour of the part. Backup and/or move forward along the part contour. Restart anywhere. Simple Jog off anywhere along part contour to restart with a lead in. User editable Operator Control Panel: This feature allows Users, Rebuilders and OEM's alike a straight forward way to change the look, feel and function of the Virtual Control Panel. Feedrate and Target Voltage Override controls: On the fly override of both Target Voltage and Feedrate via the VCP and/or the Wireless MPG knob. Wireless MPG operator control: High performance wireless control pendant with large MPG Wheel for positioning the torch, setting zeros, overriding Feedrate and Target Voltage also has 4 programmable buttons for individualized operator convenience setup controls. Centroid Firmware sets this unit above the rest. Brings a nice work flow improvement to the machine operator with this handy reliable tool. Auto Torch Touch Off: Compatible with Conductive, Ohmic, Round Mounts and Floating Heads. Conductive/Ohmic can be used in conjunction Float Head/Switch and/or Breakaway Head/Switches. Easy drag and drop for Float Head and Breakaway setup menus in the Acorn Plasma setup Wizard, Auto Float Head offset distance compensation. Built in Conversational Programming: Program plasma parts with or without a CAD drawing with Centroid's Intercon Plasma. Lines, Arcs, Squares, Circles, Rectangles, Kerf offset, Auto lead in/out, auto connect radius, Mirror, Rotate, Repeat, Teach Mode, DXF in, DXF out, now available in beta and included with the Plasma CNC12 installation. Made in USA: The Acorn Plasma system was engineered, built, and tested at our Centroid facility in the USA. Robust design, Rigorous testing = Years of trouble free operation. CNC Software and Hardware designed to work together. All units ship ready to run after thorough quality control and testing. |

|||||

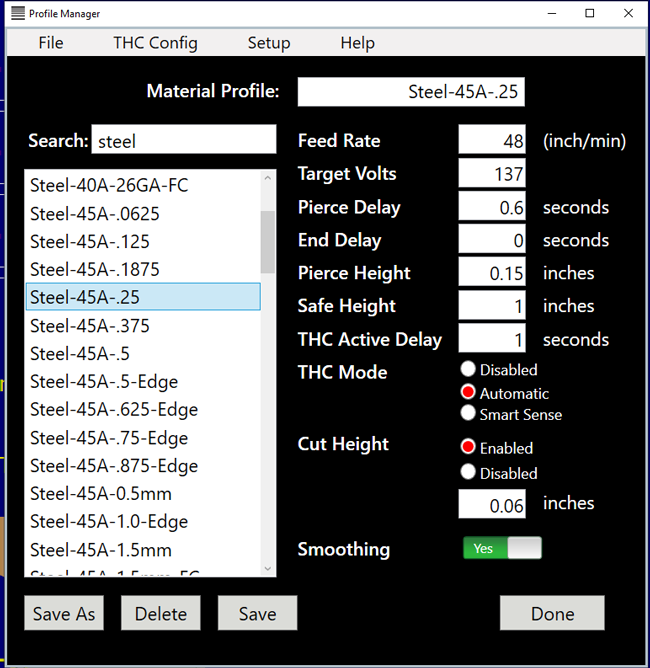

| Built-in Material Profile Manager |  |

||||

|

- Use the same part program to cut different thickness and types of metals |

|||||

?unique=9362764)