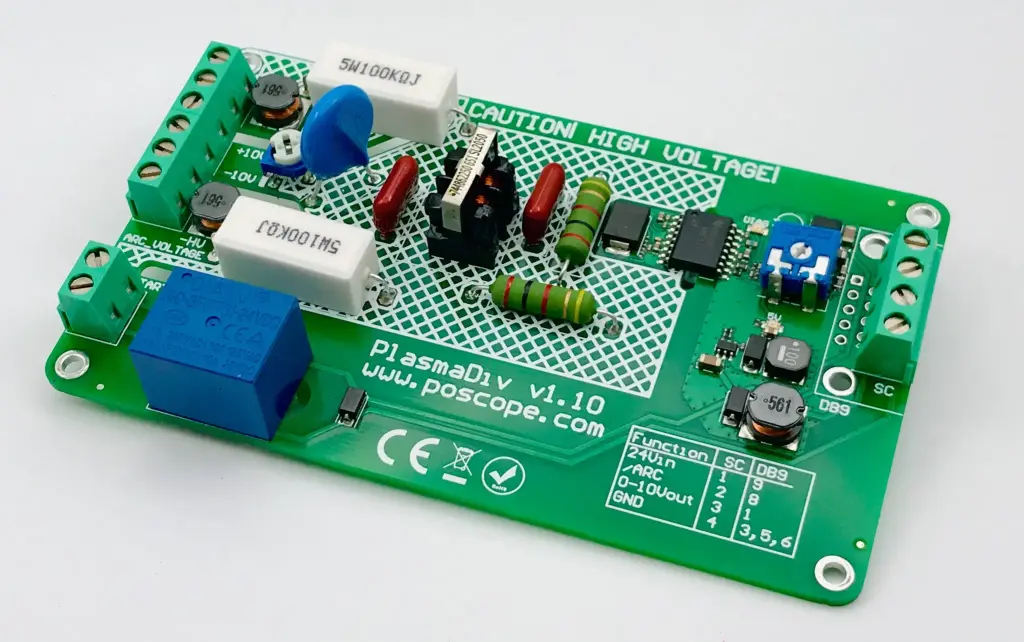

Plasma voltage divider – PlasmaDiv

Features

- Professional, precise, robust,

- High Voltage: operating range: 0-500 V, 50:1 input divider ratio , filtering cut-off frequency: 1 kHz

- Low voltage input (10V) divider ratio: 1:1,

- Isolated and filtered output voltage: 0-10 V,

- Isolation voltage (RMS): up to 1200 V,

- Isolation voltage (transients): up to 6000 V,

- Power supply voltage: 24 V,

- Start output relay signal.

- Plugin support for Mach3 and mach4, it can be operate with any CNC software and hardware without any drivers.

- PoKeys 57CNC – USB and Ethernet CNC controller or any other motion controller is needed for operation.

- To connect it to 3,3V input of the PoKeys57CNC or any controller with 3,3 V input use Adapter board 10V-3V3 or made voltage divider.

Voltage divider is a complete solution for torch height control for CNC plasma cutters. Connect it with our PoKeys57CNC to adjust the height of the plasma torch and get the most precise cuts. PlasmaDiv can be used in place of the PlasmaSensOut or PlasmaSens.

PlasmaDiv is a professional, precise, robust, galvanically isolated voltage divider with a 50:1 ratio for CNC plasma cutting.

PlasmaDiv is developed to divide high plasma torch voltage. It is compatible with most CNC controller boards on the market and plasma cutters. It has state-of-the-art filtering with efficient common-mode and single-ended filters that effectively attenuate noise from the arc voltage. The output of the PlasmaDiv is 0-10 V that any standard electronics, such as A/D converters and microprocessors, safely accept. The input stage of the PlasmaDiv provides high-frequency filtering. High voltage terminals and dividers can withstand input voltages of up to 500 VDC. Additionally,an isolated and filtered 10 V input with no attenuation (1:1) is also available for plasma cutters that have an internal voltage divider.

PlasmaDiv also incorporates an isolated start signal with a relay that safely triggers the plasma cutter torch.

Related Porducts